Top 10 Reasons to explore Summa laser cutting

While your business evolves, it might come to a point where it requires an upgrade on the equipment in your facility. Maybe your current cutting method worked out well for years on end and now starts to show its limitations. Perhaps you are struggling to meet rigid lead times. Or you have switched to other applications and need to cut very intricate details. Or maybe your business is growing steadily to a high-volume production environment.

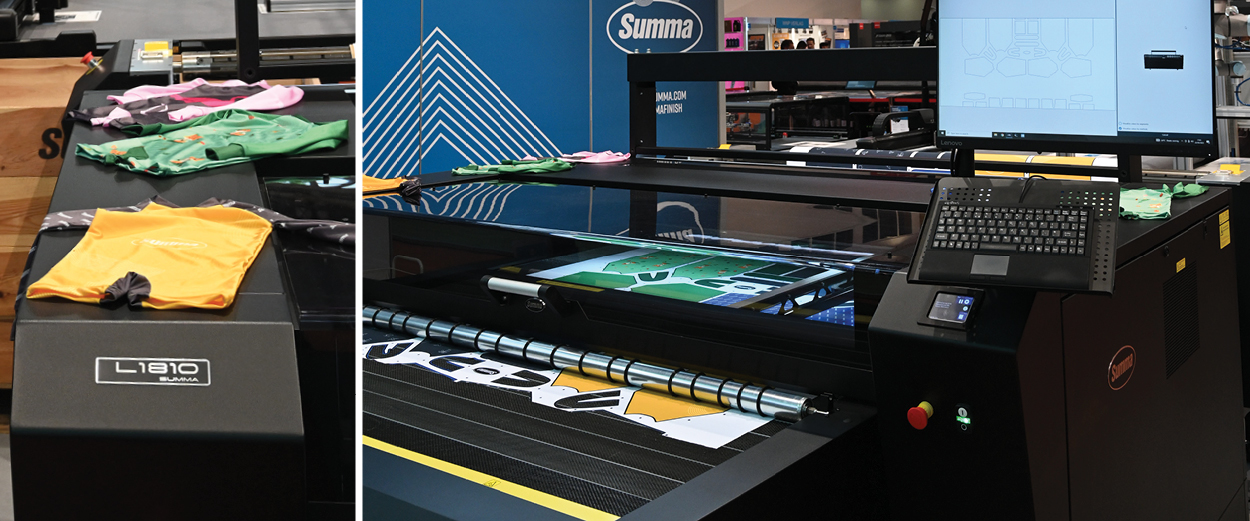

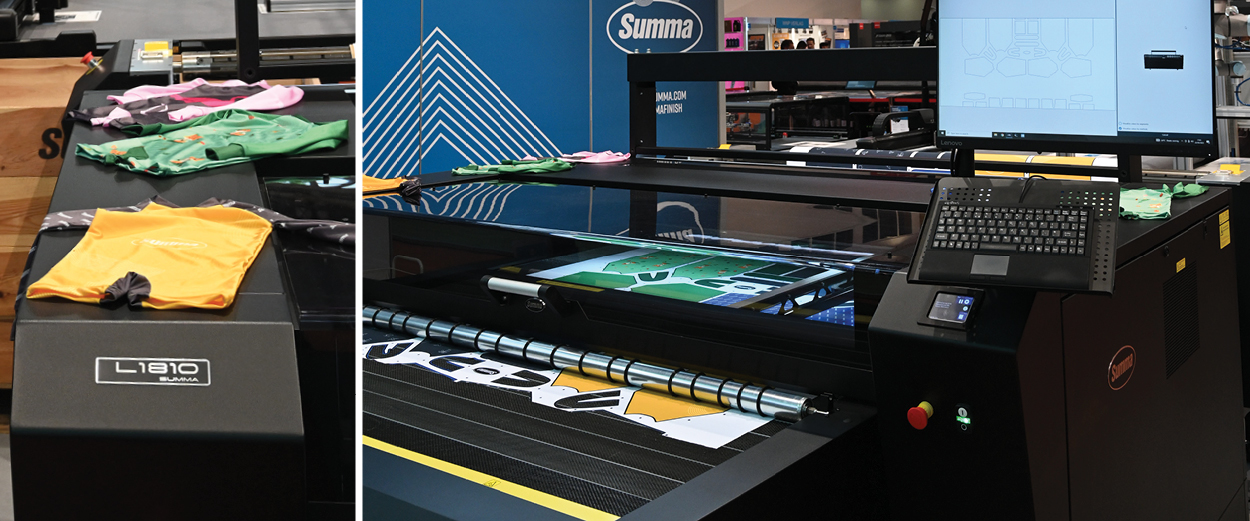

Whatever the reason, now might be the time to invest in a different cutting technology that perfectly meets the requirements of your current business. Summa offers a range of laser cutters with the L Series that might just be the game-changer you are looking for.

10 reasons to consider Summa’s laser cutting equipment:

- Your business has grown, and you need more production capacity.

If you want to bring your production capacity to a higher level, investing in a Summa laser cutting machine might just do the trick. With Summa laser cutters, you can equal your printing capacity and achieve optimal performance and efficiency. For certain cutting jobs, the Summa laser cutter is even 4 times faster than any knife cutting equipment. Read more about customized jobs in high-volume.

- You want to rely on consistent cuts each time again.

The quality of the laser source determines the consistency and precision of the cut. Therefore, Summa chooses laser sources of renowned brands. They are perfectly round shaped, create a small, focused laser beam and maintain this precision thanks to optimal temperature regulation in the laser tube. Because laser cutting is so accurate, the cuts will be exactly as designed. So, if you want to create multiple copies of the same product, you can be sure each copy will be the same. The result is consistent quality and repeatability in each cutting job.

- Your current cutting method is sensitive to distortions.

With the right equipment, warping and distortions of the material can be kept to a minimum. Summa lasers are optimized to handle even very thin, delicate materials:

1) A roll-off winding system eliminates any tension in the textile before cutting.

2) The strong vacuum system keeps the material flat on the table surface to avoid wrinkles and deformations.

3) The laser cuts through the material so quickly that the edges will not become excessively hot and warp.

4) Only the beam comes in contact with the material, so there will be no distortion of material.

- You want quality finished edges without fraying or burning.

When using knife technology to cut fabric, you will always be left with frayed edges. Or, when using cheap laser cutters that are not set up correctly, you might be confronted with burnt edges. These issues can be solved with Summa’s laser cutters equipped with a high-quality laser source. If you use the correct setup and laser power, frayed, or burnt edges can be avoided. The result is a flawlessly cut product with sealed edges that is ready to be further enhanced and finished in the sewing department. Read more about laser cutting versus traditional systems.

- You are often working with highly complex designs.

Then, what you are looking for is highly accurate cuts even in the most intricate and complex designs. Summa laser cutters include an extremely powerful laser that delivers a focused beam of light to cut the material with utmost precision. No knife cutting machine can cut with the same precision. The effect will be especially striking if you need to cut meticulous details. So, when this level of accuracy is required, Summa laser cutters are by far the best choice.

ADVANCED LASER CUTTING OF PRINTED FABRICS AND TEXTILES

Our specialists in laser cutting technology have over 25 years of experience. The knowledge gained during this time, combined with market feedback led to further development and optimization of Summa's laser machines.

- Customer demands have increased and now you require lower lead times.

Therefore, your business needs equipment that can handle jobs much faster. This is a reason to look into laser cutting, it is much faster than mechanical knife cutting methods. The quality of the laser and the wattage ensure that the material is cut lightning fast. Also, the continuous cutting – on-the-fly – while scanning in the next part ensures continuity and a much greater output. Adding to the productivity of the cutter is the smooth and flawless advancement of material onto the laser bed. This avoids downtimes and loss of precious time. So, when it comes to faster delivery times, Summa laser cutting technology is worth to explore in further detail.

- You want less waste and less material costs.

These days, limiting the ecological footprint is crucial for companies who are innovative and ahead of their time. Reducing waste wherever and whenever possible is, therefore, a must-do. Laser cutting helps in this respect thanks to optimal material utilization during the cutting process. And it will help you in return because your material cost will decrease proportionally as you will need fewer material square meters. The laser cutters by Summa can fulfil this need allowing you to place the designs close to each other in the cut file.

- You value easy maintenance of your equipment.

Surely, another great reason to go for a laser is the fact that there is no tool wear whatsoever as it is the laser beam that calls the shots. This, of course, has a direct positive effect on your tool costs as they simply don’t exist. In addition, CO2 laser cutters don’t need lots of maintenance. It is only the laser tube that needs to be replaced after intensive use. Furthermore, it is simply recommended to clean the mirror and lens now and then. With the new generation laser cutters from Summa, ease of maintenance is taken to the next level. Parts are easy accessible and replaceable if necessary.

- You are looking for automation of your production process.

By automating workflows the production process becomes more efficient. The laser cutters from Summa combined with the GoProduce software have several possibilities of automation delivering true operator comfort. A Material Manager with pre-sets helps the system to automatically recognize the correct settings to process the job. Moreover, with a Vision System you can even process jobs without the need for cut files. This is called Trace & Cut, the camera detects a black outline and automatically creates a vector and starts cutting. Another very strong feature is Barcode, enabling you to process an entire roll with different cutting jobs, without operator intervention.

- You want to ensure business continuity with a reliable system.

Summa laser cutters are equipped with long-life laser tubes and high-quality electronics, which makes a Summa laser cutter well worth the investment. Then you will not find another similar product in the market that will be your companion for such a long time and, at the same time, generate that much business and output for you and your company. Continuously. Moreover, the next generation laser cutters have field upgradeable options enabling the equipment to grow with your business.

Why a Summa laser?

Summa laser cutting technology provides high-level capabilities for many cutting assignments in the soft signage, sportswear, technical textiles and sign & display industries. The speed, productivity, automation, and the low maintenance required for Summa lasers are highly beneficial. Choosing Summa means a rewarding business investment for many years to come.

If you are interested in a demo on a Summa laser cutter, please contact us.

Why The Look Company invests in three L3214 laser cutters

"The Summa laser cutters and their excellent customer support has proven to be a winning formula for us here at The Look Company (...)"

29/06/23

Daphne Mertens & Elice van Es