Flatbed Cutter Tools

An array of possibilities within every module and tool

The versatility of the F Series flatbed cutters is greatly underlined by the multifunctional head, that is able to hold up to three modules at once. This enables users to perform multiple techniques in one single job, without interruption to switch tools.

ONE MACHINE, FOUR MODULES, COUNTLESS POSSIBILITIES

No other machine can match the versatility and adaptability of the Summa F Series. Its robust construction, accuracy and multi-functional head allow you to install up to three tools simultaneously. Choose from a wide range of options, making countless applications possible. Since the tools and modules can be added at any time, upgrades are easy and cost-effective.

Drag Module & Tools

Make notations with pens or kiss cut a wide range of materials, using a drag knife with a pressure of 600 grams of downforce. Multiple Drag Modules can be put on the multi-functional head to allow both kiss-cutting and drawing without the need to dismount modules.

Ideal for use in the following materials:

- Paper < 200 gsm

- Adhesive vinyl

- Adhesive PVC banner vinyl

Pen Tool & Universal

Pen Holder Tool

Attached to the Drag Module, this fast and accurate tool allows precise drawing on a range of materials, using either our own brand of fiber tip pens or a variety of third-party pencils and pens in a multitude of sizes and diameters, using the Universal Pen Holder Tool.

Drag Knife Tool

The Drag Knife Tool is specifically designed for fast kiss-cutting a wide range of material. With 600 g of force, this tool is ideal for cutting through a wide range of adhesive types of vinyl.

Tangential Module & Tools

The powerful tangential module is equipped with Summa's True Tangential Technology. It offers a vertical force of 10 kg and a horizontal force of 20 kg. It corresponds to a wide range of matching tools. Each of the many and varied tools have a barcode ID that ensures automatic recognition and parameter settings. Discover all the cutting techniques with the 8 tools that fit in this module.

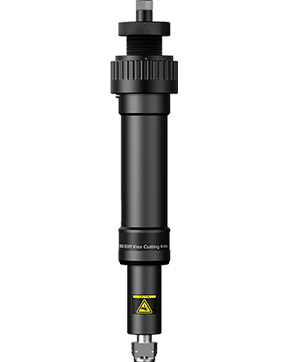

Kiss Cutting Tool

With mechanically-controlled knife pressure, this tool is specifically designed for kiss-cutting material down to its liner up to 1.2 mm thick. This tool also includes an adjustable nose piece for precise depth control.

Single Edge Cutout Tool

The Single Edge Cutout Tool is designed for detailed cutting through materials up to 6 mm thick. A spring-loaded gliding disk allows cutting of very precise details and can be fixed at a set depth.

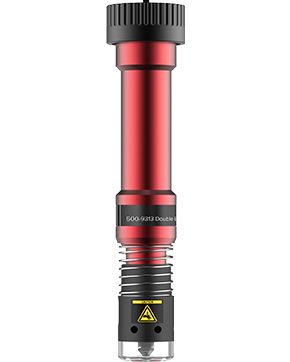

Double Edge Cutout Tool

The Double Edge Cutout Tool ensures minimal wear when cutting through rigid materials up to 5 mm thick. A spring-loaded gliding disk allows cutting of very precise details and can be fixed at a set depth.

Heavy Duty Cutout Tool

The Heavy Duty Cutout Tool is suitable for cutting through thicker material up to 15 mm thick.

Various Creasing Tools

The Creasing Tools are designed in several radius sizes and depth configurations to create folds in a variety of materials, such as paper, cartons, polypropylene and PVC material.

Various V-Cut Tools

The V-Cut Tools are available in 5 angles and are designed to cut a V-shaped groove in rigid sandwich and foam composite boards up to 27 mm thick, depending on the material’s density.

Electronic Oscillating Tool

The EOT is ideal for cutting soft and medium-density materials, designed for cutting through material up to 10 mm thick and lightweight material up to 18 mm thick. This tool is driven by an electric motor, producing up to 12,000 rpm and moves a knife up and down over a stroke of 1 mm.

Pneumatic Oscillating Tool

This tool is available in two types. The POT is powered by compressed air and moves its knife up and down over a stroke of 8 mm. It is designed to cut through thicker, stronger and more rigid material up to 25 mm thick. The POT-L has a long knife to cut thick, soft material with a minimum thickness of 20 mm and a maximum thickness up to 42 mm.

Perforating Tool

The perforating tool is used to make perforations in a very efficient and fast way. By using this tool, the perforated materials will be a lot easier to bend or fold. This will save considerable time in the assembling of, for instance, cardboard or polypropylene boxes.

Bevel Cut Tool

With its short, stable knife, the bevel cut tool is perfect for cutting V-shaped grooves into stiffer materials, such as deco felt, and rubber. The tool also excels at creating flawless folding lines solid board. When used for cutting packaging the tool imparts a quality appearance to luxury packaging.

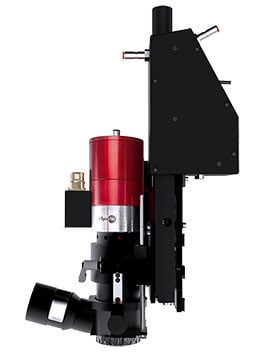

High Torque Rotary Module

The High Torque Rotary Module on the Summa F Series is driven by an electronic motor and is capable of handling all kinds of textiles. Thanks to extra rotational power, the HT RM is also able to cut tougher and thicker substrates, such as banner material.

In general, the vacuum table has less grip on textiles. However, the Rotary Knife produces minimal horizontal forces, ensuring the material stays in place. Consequently, also extremely porous material can easily be processed with the HT RM.

High Frequency Router

The High Frequency Routing Module is equipped with a high-frequency spindle and increased power output, which allow for higher processing speeds. The utmost balanced, high-frequency spindle provides for a much smoother finishing of rigid substrates. The bit is pneumatically controlled and can be replaced manually in a fast and simple way. This maximizes the productivity of the cutter when processing, for instance, acrylics, wood and plastics.

1400W router

The 1400W router offers an attractive performance increase with improved output quality over the standard router. The router is capable of handling the most used solid boards in the Graphic Industry. It is suitable for milling, contour cutting, polishing and engraving.

Standard router

The Standard Routing Module has a 1 kW motor, capable of handling most solid boards in the graphic and sign industry. Hard foam PVC, acrylic and aluminium covered foam boards as well as other materials, such as wood and MDF can be processed.

Routing bits

A wide range of routing bits enables you to get the most out of your Routing Module. Bits are available for materials such as Corrugated plastic, Hard foamboard, Polycarbonate, Foamboard with aluminium, MDF, Foamboard with plastic and Plexi. Discover how you can enhance the finishing of your jobs.