Customer Stories 03/01/2022

Comeco Gráfico S.L.U. is a company specialised in printing and graphic arts backed with more than 25 years of experience in the graphic industry (digital, offset and printing). No matter the volume: magazines, newspapers, catalogues, and stationery are produced daily.

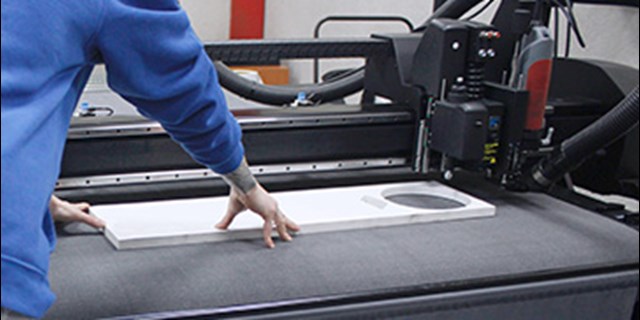

The company has been using Summa’s cutting equipment for a while. Since 2019, their F1612 flatbed cutter has been up and running to help process all kinds of material types for the packaging industry. Recently, the company bought the Summa F3232 flatbed cutter, the bigger version of the F1612 for large-format jobs. This cutting system is particularly useful when processing large board materials, or heavy banner materials and light to non-stretch wide textile rolls. All while meeting the highest quality standards.

A machine to grow with the expansive large-format workload

Because of the growth in their large format workload in recent months, Comeco Gráfico decided to buy an additional larger flatbed cutter while maintaining the existing productivity. They have chosen a second Summa-product because of the user friendliness, reliability, and flexibility the Summa F1612 gives. Even though both machines are used for the same type of jobs, each in its own format, the production loads can now be distributed across the two cutters, providing more flexibility and workflow efficiency.

Pedro Iglesias, Section Head of production at Comeco Gráfica explains: “The two machines are essential. Given the number of machines we have in our facilities, it makes no sense to process two-by-three-metre materials and then not be able to finish them on site. The cutters are currently handling the work coming from three painting tables and four large-format web printers. They allow a chain of work from the painting table or printer to the cutting table and on to the next stage of production. We see that the cutters are capable of handling the load of even more devices.”

To view this content, you need to accept functional cookies.

Change cookie preferences

Minimal difference in jobs apart from format

While the F3232 takes care of the large-format jobs, the functionalities of the smaller F1612 are not inferior to its big brother. Comeco fitted the F1612 with a milling kit, not the F3232, because these applications are hardly done at such large sizes. Apart from that, the same tools are used on both cutters, proving the versatility and compatibility within the F Series range from Summa. Posters, banners from small to large, packaging, various signs and cardboard displays, stickers, nothing is too much for Comeco Gráfico.

An easy installation of a big machine

Despite the large size of the F3232 flatbed cutter, installation did not take long. In less than a week, two people from Summa partner Rotutech had it up and running. While the installers collected the boxes and the plastics, it was a pleasant surprise for Comeco Gráfico that they were able to start using the flatbed cutter right away.

Comeco Gráfica’s relationship with Summa does not end with this new cutting equipment. As a growing company, they are always considering new innovations to meet the high expectations of their clients. For example, there are modules and tools that might come in handy for the cutting of textiles, which are printed on four large format plotters. Also, the new perforation tool could save time on some packaging applications. All aspirations to meet the customer needs and keep delivering the best for their clients.

The Summa F3232 flatbed cutter was purchased, delivered, and installed by Rotutech. Also distributor Cyan SA was involved in the sales and installation process.