Industrial 01/01/2020

When processing fabrics, it remains a big challenge to utilize fabrics optimally with a minimum of waste. Besides nesting designs on the fabric, it is also a matter of not to overproduce. But to accomplish this, a few hurdles need to be taken first. The challenge here lies in finding ways to optimize the entire workflow. This also involves the cutting process with choices such as pre- or post-cut, multi-ply or single-ply and choosing to cut manually or with a laser cutter.

It is easy to make the link from fabric optimization to the circular economy. Which refers to a system aiming at eliminating waste and continual use of resources. Increasingly more businesses aim to contribute to the circular economy to give their products and materials a longer life span. This has a positive effect on the ecosystem and avoids the exploitation of the environment. At the same time, optimizing the use of fabrics has a positive influence on the business’ yield and overall economic growth.

Ways to contribute to this more sustainable manner of production start with an evaluation of the entire workflow. For instance, when you are using a sportswear workflow with pre-cut, as you might know, means that the parts with which a sport shirt will be made, are cut prior to applying the print design. Chances are that there are too many pieces cut. And because they have no purpose within that job, they easily end up in waste.

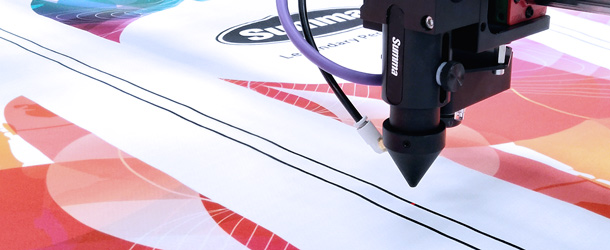

Therefore, non-conventional optimization methods applied in the cutting process can provide the change that is needed. You can consider post-cut with a Summa laser cutter, that works by first preparing the print design and calendering, then laser cutting the material afterwards. By succeeding to do this, production costs will automatically be minimized, whilst maintaining high-quality products and reducing the amount of fabric waste.

Because every square inch of the fabric counts for the organization, ánd environment, it is clear that it is beneficial to set up an efficient workflow. After the evaluation of your current workflow, you can pinpoint the bottlenecks and recognize critical areas to optimize.

A good production flow requires seamless coordination between hardware and software. Therefore, investing in powerful software is more of a necessity than a luxury. Good software helps to implement efficient nesting methods in the design stage and reduces the risk of human error through a well-arranged interface and presets. Take for instance the F Series flatbed knife cutters that are perfectly aligned with Summa's own GoProduce software.

Also, smarter marker positioning and precise consumption calculations for different garments help reduce fabric waste considerably. In short, it is indispensable to implement fabric-saving methods at different stages of the production process.

Summa’s L Series laser cutters are equipped with many features that boost productivity and contribute to the responsible use of materials. Also, ease of use, accuracy, safety and efficiency are characteristic of the machines' functioning.

We mentioned it already, nesting is very important to reduce fabric waste. With the software of the Summa laser cutters, users can put the designs close to each other. This, obviously, should and is supported by the cutting technology used in the machines. For instance, the cutters read the registration markers that are printed on the fabric. And the software makes sure that margins around the markers are at a minimum or even that markers are placed in the design. Moreover, when you cut flag-sized designs, you can enjoy cutting without markers through Summa's Vision technology. This works through advanced camera recognition, after a scan of the design the software automatically prepares the cutting file.

With Summa, the nesting happens in the design phase where it will be printed on the rolls first and cut afterwards (post-cut and single-ply). With this method, you can achieve higher production efficiency and less waste. But it requires a total change of a conventional workflow such as multi-ply cutting of multiple layers where nesting happens manually on the table itself.

The ease of use of the machine is closely related to production efficiency. That is why each laser cutter is enhanced with convenient media handling options. While being efficient, the machines are maintaining the cutting quality at all times.

The roll feeder is a good example of this. Before cutting, the system eliminates any tension in the textile while it feeds the textile to the machine. In addition to that, a conveyor belt with specially designed slats continues to transport the fabric totally relaxed through the cutting machine. This way, there are no sizing issues nor cutting errors with precise cutting as a result.

The Vision technology on the laser cutters is unique to Summa. The advanced camera detects shapes automatically and cuts these on the fly via an intuitive AI system. Consequently, the laser can keep on cutting while transporting the fabric on the fly. No more idle periods and an accurate cut each time.

What’s even more, in contrast to multi-ply machines, we don’t need to calculate a buffer around the cut design. That is because the laser beam always has the same shape in contrast to the knives. Knives will wear down and can even shift a little, which will lead to less accuracy when cutting. In that situation, you would need a buffer to intercept these inaccuracies and unfortunately create more waste. The laser beam will always cut at exactly the same place in the fabric, thus minimizing fabric consumption substantially.

But sustainability doesn’t stop here. It is also seen in the longevity of our Summa products, both laser cutter and our other ranges. Their robust construction, reliable technology and versatility ensure they will still meet your business needs in many years to come!