Tech Review 22/11/2021

Whether you’re a startup or a weathered professional, many factors come into play when you decide to invest in a cutting solution. Not only do you have to think about which characteristics and functions would be most beneficial for your company, but there are also many different types of cutters to choose from. At Summa, we understand that this process can be quite overwhelming and sometimes even confusing. That’s why we created this guide! After reading, you will have obtained all the information you need to make an informed decision about your perfect cutting solution.

Asking yourself: Flat-whats and roll-huhs? Before we dive into the details, it’s crucial that you understand what we mean when we refer to roll cutters and flatbed cutters:

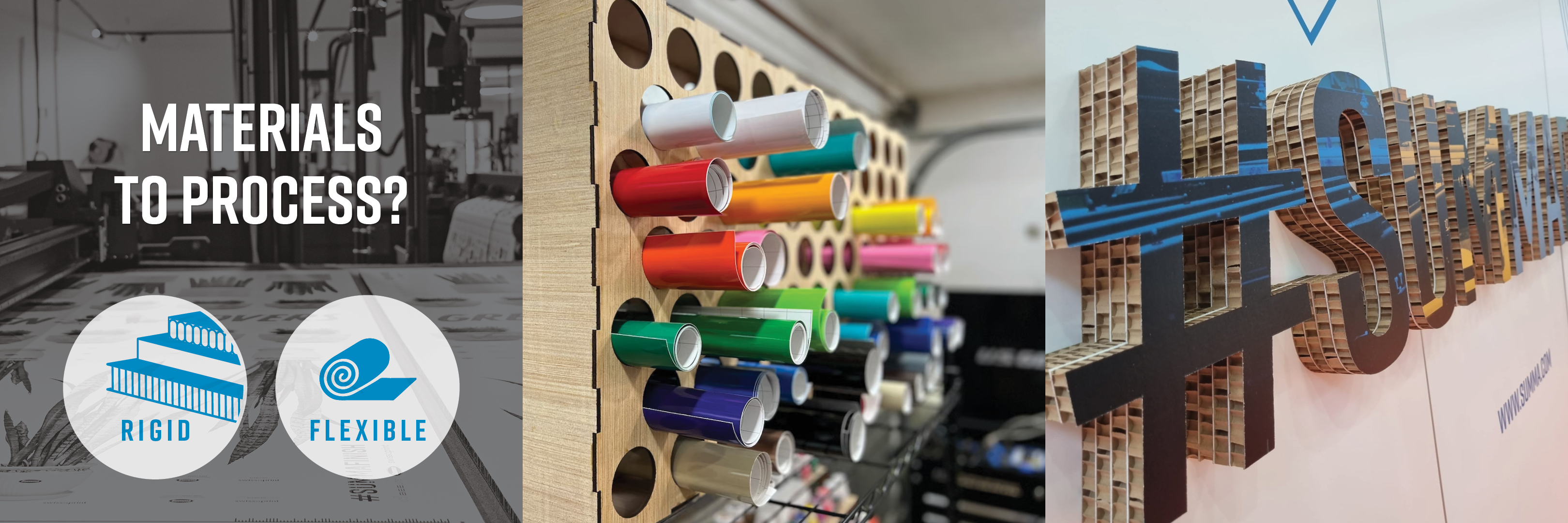

This first difference has already been addressed when we defined both cutters, namely the type of material that the cutter can process.

A roll cutter can only cut flexible materials on rolls, such as vinyl. However, if you add a sheet feeder to the roll cutter, it can process flexible materials that are not on a roll, such as folding carton or loose vinyl sheets.

Flatbed cutters are much more versatile than roll cutters. Not only are they capable of handling both flexible and rigid materials - this includes all kinds of cardboard, roll, synthetic, and industrial materials, as well as composites and textiles - they can do more than just cutting. Flatbed cutters can route, engrave, and polish as well.

When working on industrial applications, we recommend investing in a flatbed cutter, even if you only need to cut flexible materials, as those types of materials tend to be a lot more difficult to cut.

The size of the materials and/or prints that you use can also influence your choice.

Summa roll cutters can handle media of up to 167 cm wide. Anything wider, and you need to go for a flatbed cutter. The largest flatbed cutter Summa manufactures, the F3232, is both 320 cm wide and long. But that does not mean that you are limited to those dimensions. With a flatbed cutter, it's possible to cut materials that are longer than the table length. The F1612, for example, can cut sheets that are max. 160 cm wide, but they can be as long as you want them to be.

The floor space you have available is particularly important when choosing a flatbed cutter, as it can have a major impact on your purchase. Depending on the model, a flatbed cutter could take up a good amount of space.

In fact, the smallest Summa flatbed, the F1612, takes up a bit more than 5 m², while the F3232 has a whopping 18 m² surface area. Even if you don’t have that much space, with the smallest flatbed, you can still cut sheets longer than your flatbed cutter, which is perfect for companies that process large sheets but have limited space.

Floor space is not as much of a decisive factor when it comes to roll cutters, as they don’t take up that much space. The smallest Summa roll cutter is the S1 60. It’s our desktop model and takes up less than 1 m², while the largest roll cutter, the S3 160, has a surface area that is just above 2.5 m². All-in-all, they are considerably smaller than a flatbed cutter.

Your current and future projected amount of production is important, especially when thinking about investing in a roll cutter. If you have a low to medium production amount, we recommend the S One Series. However, if the material you want to cut is laminated, the S Class 3 Series would be a better choice.

If you have a medium to large production amount, we are also in favour of the S Class 3 Series, as it is faster while getting top-quality cuts. It’s also capable of creasing in short runs.

The impact of production volume on the flatbed cutters is only a decisive factor if you need to produce a large amount fast. Generally, all Summa flatbed cutters have the same amount of speed and power and can handle the same tools. Read more

However, the F3232 has a special function called tandem mode that makes your workflow more productive. Your work area is split into two, so when the cutter is done cutting one piece, it automatically starts on the second sheet in the other area, giving the operator enough time to take off the completed sheet and place another. This ensures the machine is cutting 100% of the time while simultaneously eliminating the time it takes an operator to change sheets. Watch a demo

If you are still not sure about which machine would fit your company? Download our free flowchart to help you make your choice!

For more in-depth information, we invite you to explore our website, download our brochures, or visit one of our local dealers. If you'd like to witness the capabilities of our cutting machines in action, don't hesitate to schedule a demo!

Remember, the right cutting solution can significantly impact your company's productivity, efficiency and growth potential. Summa and our partners will be happy to help you make a careful choice! Contact us