GoProduce 3.0 Flatbed Edition

Developed to perfectly match your F Series flatbed cutter

SOFTWARE TO PERFECTLY MATCH YOUR F SERIES

GoProduce is the first software module within Summa's GoSuite platform. It is developed to handle jobs easily and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

New! GoProduce Flatbed edition V3

GoProduce Flatbed Edition has undergone a major update. It is now available, and it has some great new features!

Enhanced Routing Features

New advanced features are introduced, such as automated detection of drill hole placeholders and the ability to choose a cutting starting point outside the shape for high-quality cuts.

Powerful 64-bit Software

Not only does the software run faster, but there is now more working memory, and it operates more efficiently.

Connected Media Handling

Integrate your flatbed smoothly with peripherals to create an efficient automated workflow, using our GoConnect software integration.

Behind every flatbed cutter,

you will find powerful software

The standard GoProduce software - included with all F Series models - embeds various functionalities. To maximise your F Series' use, the optional GoProduce Pro Pack offers even more functionality.

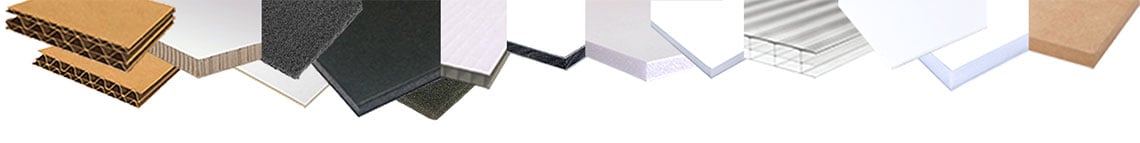

Material Manager

GoProduce contains a convenient material database, which includes an extensive range of material types and can be adapted to your specific needs. The Material Manager offers added value by working with methods, meaning that you only need to choose the material you want to process and the material manager itself automatically chooses the correct tool and its settings to process it with. More

Sorting

In order to minimize output time, the order in which objects are handled is very important. GoProduce has the capability of determining the start and end of a vector, as well as the order of processing. The aim is to shorten the traverse path. Basic sorting is done by GoProduce itself.

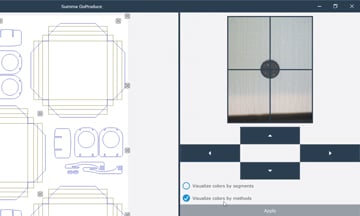

Camera recognition

The recognition process, localisation of the registration marks and the process itself can be tracked in the camera preview window. All kinds of compensations and marks, which occur in everyday practice, are manageable with GoProduce – whether they are printed on film, textiles, cardboard, etc.

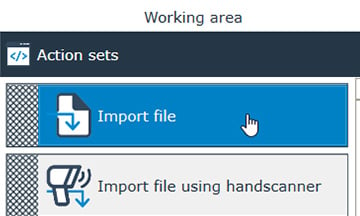

Custom configuration of action sets

The flexible action sets enhance workflow automation and enable users to tailor the workflow to their needs. This way, jobs can be handled in a natural, trouble-free and straightforward way.

Back side cutting with edge detection

In GoProduce 1.10, a new camera profile is added to read the marks and detect the edges of the sheet. This way, the machine will start the process immediately, without the need to cut out the marks first. This feature makes it easier to protect the print while saving the operator valuable time. See how it works on this video.

Tutorials and Knowledge Base

Various tutorials are created to support you in the installation and use of Summa GoProduce. Watch them all on Youtube.

Knowledge base available on www.summa.com/faq

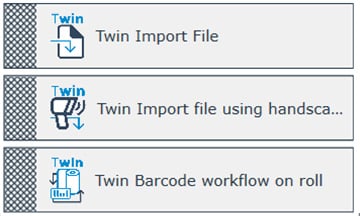

Barcode functionality (Pro Pack)

The barcode functionality reads the printed barcode and automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically (or alternatively by hand scanner). See how it works in this video.

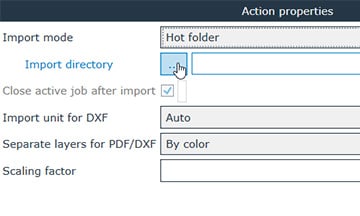

Hot Folder Support (Pro Pack)

With the hot folder functionality in GoProduce 2.0, files dropped in a folder can now be opened automatically in GoProduce. Error-detection and handling of bad jobs will be done by this feature, so the appropriate job can be cut instantly without lingering.

Twin X Workflow (Pro Pack)

Twin X is a new type of workflow enabling GoProduce to read cutting files prepared for Summa Roll cutters. This way the Twin workflow, previously only available on OPOS CAM roll cutter units - can now also be used on all Summa roll cutter units, equipped with an OPOS X sensor.

GoProduce software tailored to your business needs

Thanks to targeted GoProduce features, you decide how to tailor and use the software and operate your Summa flatbed cutter as efficiently as possible. Are the standard integrated features sufficient or do you wish to use the Pro Pack? Choose your level of software advancement according to your specific cutting requirements.

GoProduce Flatbed Edition V3

Standard available with every F Series unit

- Customizable action sets

- Mark recognition

- Print & cut compensation modes

- Material manager

- Cut only with edge detection

- Backside cutting over multiple segments with edge detection

- Tandem mode

- Advanced routing options

GoProduce Flatbed Edition V3 Pro Pack

One-time Pro version purchase

- Customizable action sets

- Mark recognition

- Print & cut compensation modes

- Material manager

- Cut only with edge detection

- Backside cutting over multiple segments with edge detection

- Tandem mode

- Advanced routing options

- Barcode functionalities

- Hot folder

- Import plot files

- Export to PDF

- Extra supported file formats: .svg, .zcc, .cut

Your material manager

This is why you will love the Material Manager in GoProduce:

- 25+ materials and presets for your F Series

- Materials include specs such as thickness and distinguishes between flexible and solid materials

- Create your own preferred materials and presets

- Work smart, each material is linked to matching tools and its settings

- Easier for your designer, no need to know the required tool in advance

Two ways to efficiently scan in your job

With the built-in camera

Through this setup, scanning happens automatically, job after job. The job will be opened in GoProduce to be processed immediately and the camera searches for the next job without operator intervention.

With a hand scanner

The hand scanner increases the flexibility of the operator's workflow. By scanning the job manually, operators can quickly switch between jobs and materials. Multiple, different jobs can be processed back to back with ease.

Get the most out of your flatbed cutter

An advanced flatbed cutter is not complete without suitable software. GoProduce is developed with the user in mind. That is why you can organize the software interface to your preferences.

Read more on how GoProduce can help to increase the usability and productivity of your hardware.