L3214 Laser Cutter

Meet your customers' deadlines and improve your margin

The L3214 Laser cutter is the most productive solution for cutting wide-format soft signage. The key to its productivity is a unique on-the-fly cutting concept to ensure a perfectly cut product, ready to roll off the table.

BOOST PRODUCTIVITY IN WIDE-FORMAT LASER CUTTING

Increase your production efficiency to the highest levels without compromising an inch on cutting quality.

Vision Camera System (standard included)

At the core of the enhanced productivity lies a high-quality camera recognition system, called Vision, which is standard included on the L3214 laser cutters. The Vision camera continuously scans the fabric and automatically creates the cut vector needed for the job. The cutting happens on-the-fly, enabling the L3214 to cut continuously, even when the conveyor is moving.

Maintain high accuracy levels at top speed

A motorized edge-detect unwinder eliminates fabric distortion while cutting by securing a constant and stable fabric feed onto the cutting bed. A loop in the material is created to relax the material, reduce distortion and secure an accurate cut. No more idle periods, yet boosted productivity with a perfectly cut product, ready for shipment or further processing.

Next generation conveyor system

Summa's conveyor system for the L Series is ideal for the continuous production of rolled material, as it automatically transports cut parts out of the machine. The metal slat construction of the conveyor allows for vacuum extraction from underneath. The material will be held down by means of the vacuum, which will result in a clean cut and precise transport movement through the working area.

High-quality laser tube

The laser cutter is equipped with the best quality sealed RF laser source. The laser system uses contactless cutting, meaning there is no drag on the material and no blades to change. It enables users to process sensitive and easily distorted textiles with high precision.

Classified safety system

For safety and environmental reasons, fumes are removed by the internal extraction system. Some residue can be produced when cutting but this is removed from the cutting chamber by the extraction system. This way, a clean work environment is maintained. The L3214 meets the Class 1 standard, ensuring the laser cutting source is covered during operation and paused when the cover is opened.

Cut-to-Frame functionality

The standard included Vision camera allows to cut material to frame, enabling a perfect fit into SEG (Silicone Edge Graphic) frames. Any shrinkage or deformation that occurred during printing and calendering is automatically detected. The position of the cutting data is calculated and placed in a way that the image fits flawlessly into the intended frame size.

How the L3214 laser cutter achieves its high productivity

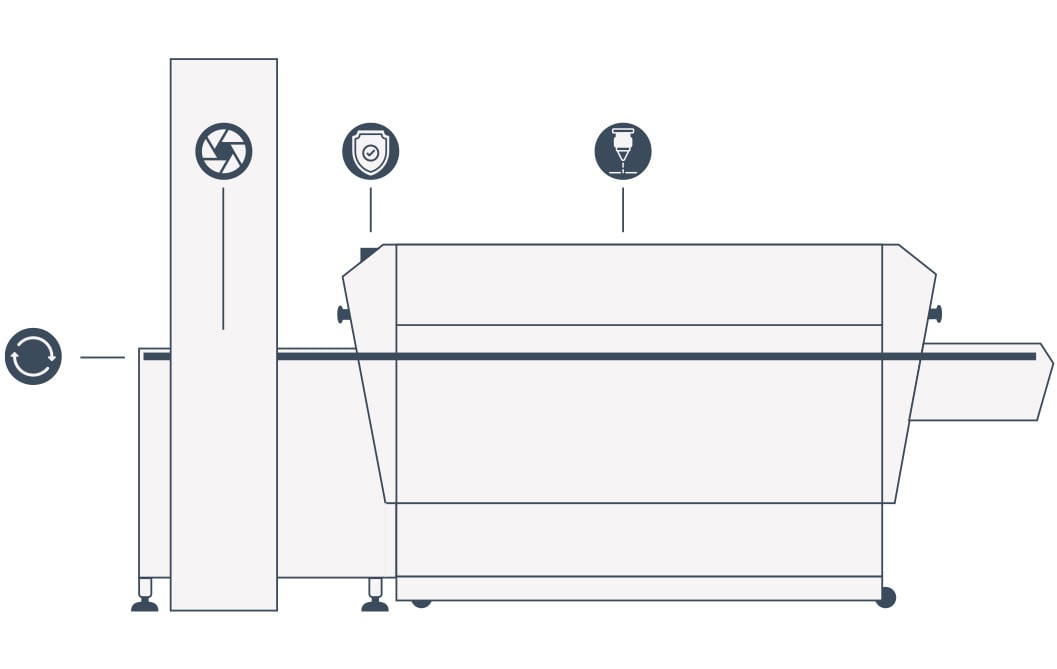

The drawing above indicates the key points of the L3214

- The unique on-the-fly cutting concept ensures a perfectly cut product, ready to roll off the table at an incredible speed. This enables L3214-users to serve their customers faster while maintaining high accuracy.

- The L3214 cutting workflow starts with a straight feed of the material through the motorized edge-detect unwinder.

- Then the design is scanned in and a cutting vector is automatically created.

- After that, the material is cut while the next part of the job is scanned in, simultaneously.

- Illustrating the high productivity of the L3214: when processing typical jobs, the machine even cuts 400 m²/hour.

Excellent Cut-to-Frame processing

Cutting banners to frame can be a real challenge. Entrust your cut-to-frame job to the L3214 laser cutter, so everything fits like a glove.

To view this content, you need to accept functional cookies.

Change cookie preferences

| MODEL | L3214 | ||

| LASER POWER | 250 Watt (water-cooled) | ||

| MAX CUT WIDTH x LENGTH | 3300 mm x continuous | ||

| MAX ROLL WIDTH | 3400 mm | ||

| SPEED |

|

||

| CAMERA RECOGNITION |

|

||

| FEATURES |

|

||

|

STANDARD SOLUTION INCLUDES |

|

||

|

OPTIONS |

|

||