Tech Review 22/11/2021

Nowadays, information about cutting technology in cutting plotters is everywhere around us. It reaches us through professional trade magazines, brochures, social media or simply through word of mouth marketing. And perhaps a little bird might have told you about drag knife or tangential knife technology. But despite the overload of information from the above-mentioned channels, what exactly are these cutting technologies all about?

The most frequently used cutting technology for plotters is the drag knife or swivel knife technology. To explain what it is and how it works I generally use the tractor plough as an analogy.

The first factor they have in common is that both tools, drag knife and plough, are being ‘dragged’ through their substrate. For the plough, this will be earth or dirt while for the drag knife this will be vinyl or foil.

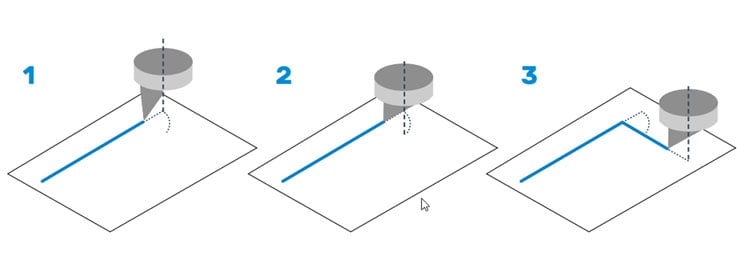

The second factor they have in common is that both tools are controlled by external elements. For the plough, it will be the tractor, which makes a movement by literally ‘pulling’ the plough to orientate itself in the correct direction. For the drag knife, it will be a combination of the cutting head movement and the media movement. Both movements enable the knife facing in the right direction because the knife itself can rotate freely in the knife holder.

Considering this, one might ask himself: How does one make such sharp corners, whilst using a drag knife?

It might come across as a shock, but you actually never make sharp corners with a drag knife.

The drag knife needs to make certain movements in each corner without the ability to lift from the media to make a “sharp” corner. At least that is the theory behind it. Since all these extra movements are done at a minuscule level, it is practically impossible to see this with the naked eye. In its own way, a drag knife might just do the trick, depending on the substrate and the kind of job you want to cut.

The drag knife is definitely the tool to use for cutting designs for billboards, light boxes, window graphics,... However, depending on the thickness of the media, the more visible distortions or deviations in the corners will become. Sometimes, slightly rounded corners or media is being pushed up, depending on how soft or rigid the media is. Some could point out that the amount of pressure you can use on the drag technology is limited, which is true. However, there is a certain logic to this. Then higher pressures are generally used for thicker and harder media. But the drag knife technology simply isn’t very suited to cut these kinds of rigid substrates.

While the drag knife technology has its limitations, it is still a powerful and widely used technology. That is why the S One is one of the most popular series of vinyl cutters ever built. It offers powerful technology with a high-speed cutting head, legendary tracking and an optical positioning system at a very affordable price. Discover how you can have reliable and effortless vinyl cutting at a wallet-friendly rate with the Summa S One series.

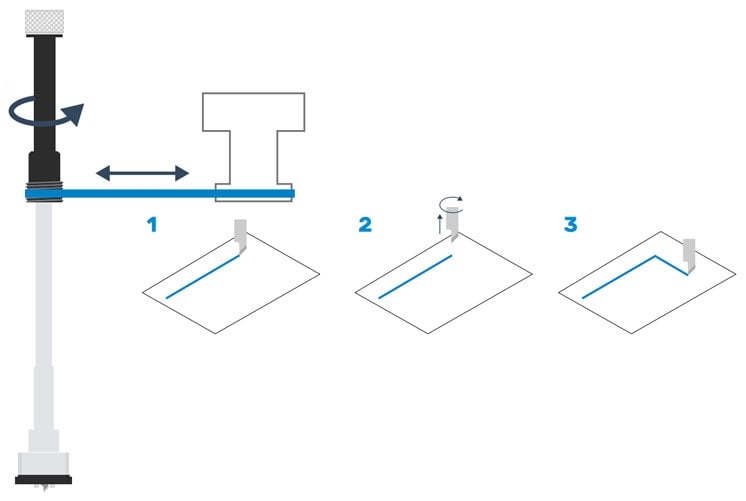

In response to the limits of the drag knife technology and the user’s specific needs, Summa has developed the tangential knife technology. Instead of a freely rotating knife, the tangential knife will be controlled by a motor. This external motor will literally position the knife in the correct angle. Whereas the drag knife remains in the media all the time during cutting, this tangential technology will lift the knife up from the media, rotate it and lower it back into the media.

The result of using the tangential knife technology will be perfectly shaped cut corners in thin media, but also in thick, rigid media. For there are no drag forces that will influence the knife’s trajectory. The tangential technology allows for much higher cutting pressures and enables you to use longer knives compared to the drag knife technology. As a result, the user will be able to cut thicker and harder substrates with the same detail and quality as if it would be cut in thin substrates. This technology is generally found on flatbed cutting machines, used to cut thick substrates. To achieve a high-quality cut in applications such as floor graphics, vehicle graphics, textile, sandblast, road and safety signs, and many more, we highly recommend using a cutting machine with the tangential knife technology.

And although bragging is not an attractive quality, honesty, for that matter, is! There is only one manufacturer that can develop cutting heads, with this remarkable True Tangential cutting technology: Summa with its S Class 2 T (Tangential) Series! Furthermore, these highly-engineered tangential cutting heads are small and light enough to fit on a roll plotter. The S Class 2 vinyl and contour cutters provide you with unrivalled, tangential technology and unmatched die-cutting precision as no other in its class.

The only other cutting device you will find with this high-end tangential technology are flatbed cutting machines. With a flatbed cutting machine, there will be no restriction in size or in weight of the cutting head. (If you are interested in a versatile flatbed cutting machine, Summa offers these in variable sizes. Curious for more, check out the Summa F Series).

One of the many advantages the Summa knife technology offers is its accurate depth control. Many people think tangential cutting technology is only useful for processing thick substrates. However, the way Summa implemented this technology on their cutting plotters allows for the operator to set the cutting depth as accurately as the thickness of a human hair.

Another advantage of this technology is how easy it is to weed out the vinyl parts. As every corner is perfectly shaped and cut by means of an overcut feature, peeling away the excess material will be done in a breeze. Even cutting meticulous details in thickly laminated media becomes a child’s play.

Last but not least, I’d like to point out that perforating material and creating tear-off lines, using Summa’s FlexCut feature, is so reliable on a tangential machine, you can safely add this to your jobs, as well. While doing so, restrictions are limited to a bare, non-noticeable minimum and possibilities are as high as your imagination can take you! Taken into account all these benefits, tangential cutter users will all say the same thing: “Don’t hesitate and put all your trust into a tangential cutter. There’s nothing like it! You’ll never regret the choice!”

Make a choice you won’t regret, check out Summa's S Class 3 Series for more information.

To view this content, you need to accept functional cookies.

Change cookie preferences