Product 29/06/2023

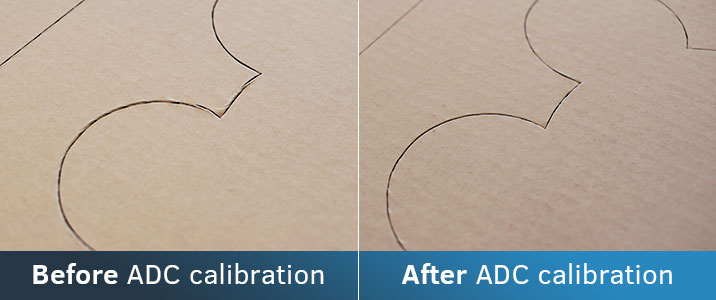

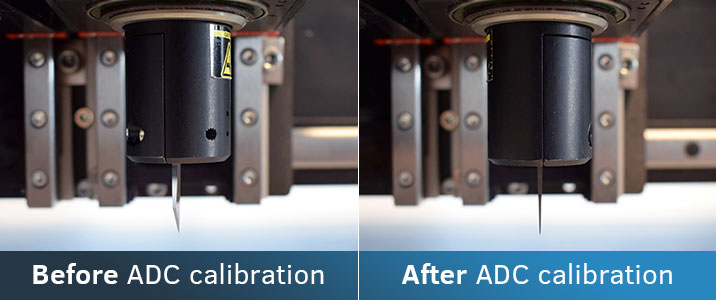

The key to achieving the ideal cut which is highly accurate, straight and cuts just deep enough, depends on the knife orientation and knife depth. This result can be easily achieved with Summa's Automated Depth Control, a feature standard included in all Summa flatbed cutters. The ADC automatically sets your knife depth and the orientation of your tool. With the ADC, your Summa flatbed cutter will perform the ideal cut each time again.

We've all been there when attempting to achieve the ideal cut. You will conduct tests on non-dispensable material and adjust the settings accordingly. Then, you wonder whether this is the best result you can achieve and just to be sure, you will conduct more tests, tweak the settings until you think to have it pinned down. Oh, and to remove all doubt, you will just do that test one more time… Hopefully, by the end of this manual process, your tool will be calibrated and cuts accurately, at least when perceived by the bare eye.

You can forget this manual labour as it is a thing of the past with Summa's "Automatic Depth Control" or ADC feature. It will make your job as an operator easier, making the self-doubts, second-guessing and countless testing redundant.

In short, with the ADC you will;

Not only does the Summa ADC provide a cleaner cut, but as it is a standard included feature on the Summa F Series, the depth control can happen automatically and every time at the same spot, each time again. When you switch the flatbed cutter on and with every tool change, the ADC will calibrate and set the depth of your knife at the right level. With the ADC by your side, the risk of setting your knife too deep and cutting into the conveyor is non-existing.

There is no need to follow an endless manual or to even have experience in calibrating knives or tools as the ADC does it for you. The calibration happens automatically for every tool, every module, even for the router module, making a tool change or a switch of material quick and easy.

Combine the ADC with Summa's GoProduce software which contains a standard included material database to optimize your workflow even further. No media will be wasted as the ADC does not require any dedicated or special material to do its calibrations, saving you not only time but money as well.

One of the most significant features and unique to Summa's ADC is the ability to calculate and compensate the knife orientation and lateral offset.

This is essential as one knife is not like the other. Every knife has been made within an approved tolerance, however, this means that each knife will cut differently.

Without any control over the knife orientation, chances are that the knife will plough through the material instead of cutting it straight ahead. This is particularly of importance when cutting rigid materials where there is a greater risk of breaking your knife.

Also, without a correct lateral offset setting, the origin of your knife can be more to the left or to right, which decreases the accuracy of each cut.

The ADC automatically compensates these derogations in order to achieve a straight and accurate cut. This compensation also minimizes the wear on your knife and contributes to a longer lifespan. The risk of breaking the knife when cutting a rigid material is also minimized as the knife will endure less friction due to a correct knife orientation.

The Automatic Depth Control feature only adds to the user-friendliness a Summa flatbed cutter can provide for you. Along with features such as automatic tool recognition, barcode workflow, in-house developed software (Summa GoProduce), and many more, Summa can make cutting as easy as ADC.

To view this content, you need to accept functional cookies.

Change cookie preferences