Product 29/06/2023

To remain competitive in the world of graphic industries, you need to make sure that your cutting equipment excels in versatility, efficiency and automation. State-of-the-art cutting machines that meet a broad range of cutting needs to respond to many industries are therefore indispensable. But a smooth integration of these cutting machines into existing workflows is just as important.

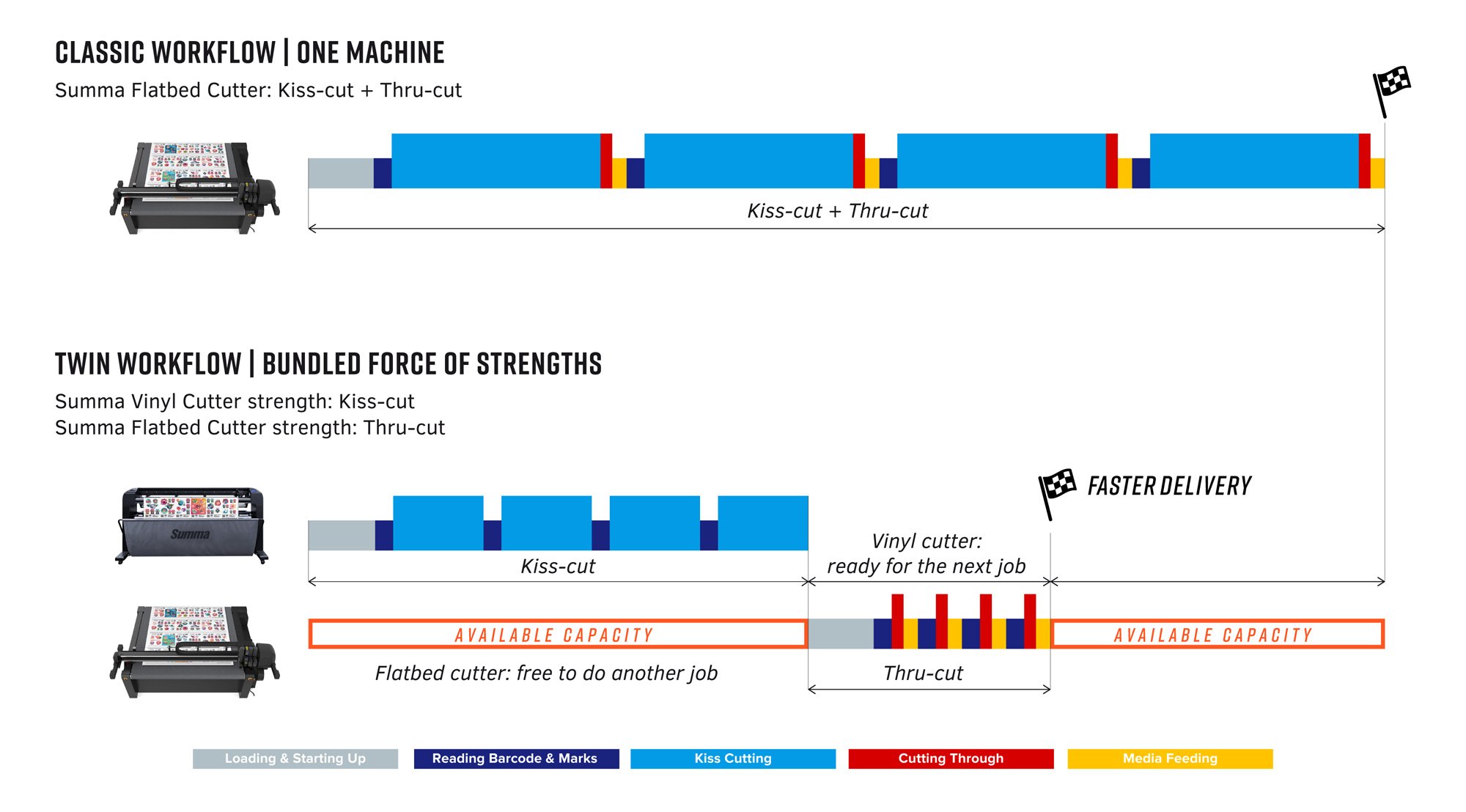

Experience teaches us that using a single cutter to perform all cutting methods is not always the most efficient method. Then each cutting machine has its specific strengths. On top of that, you can create a much more efficient workflow if you assign certain cutting jobs to the cutter who masters this specific cutting method best.

So, if you want to maximise productivity, quality and efficiency and integrate your cutting equipment seamlessly into your print&cut workflow, you can use Summa’s Twin Workflow. A leading-edge workflow that is only offered by one single manufacturer. Summa.

Cutting plotters perfectly tuned to each other

The Twin Workflow combines the strengths of a Summa vinyl cutter – S Class 2 or S One Series - and an F Series flatbed cutter. This translates into two cutters that are perfectly matched. Based on the specific cutting method, the cutter that is best suited for the job is used. So, instead of using a single cutter for the entire cutting job, the Twin workflow divides the cutting methods between both cutters. This way, the individual strengths of both machines are fully utilised.

In practice, this means that you can kiss-cut your graphic designs on the vinyl cutter by using the Summa GoSign software. Then transfer the roll that is kiss-cut to the flatbed cutter and cut it through (Cut Thru) using the Summa GoProduce software. In this way, you double your productivity and speed up your delivery times by up to 47%*.

Increased production capacity

The Twin Workflow was specially developed for operators who want to work as efficiently as possible. Indeed, by using this workflow, extra capacity is created. While the vinyl cutter is performing the kiss-cut method, the flatbed cutter uses the freed up capacity to perform other cutting jobs, such as routing, creasing or cutting textiles. This takes productivity and performance to a higher level and the smooth integration of both cutters into existing workflows will further contribute to your productivity.

Seamless integration of Summa software

The best hardware is nothing without well-integrated software. Thanks to the Summa GoSign software (roll cutters) and the Summa GoProduce software (flatbed cutters) both the vinyl cutter and the flatbed cutter can process the same cutting files and registration marks. This is crucial to guarantee a smooth Twin workflow.

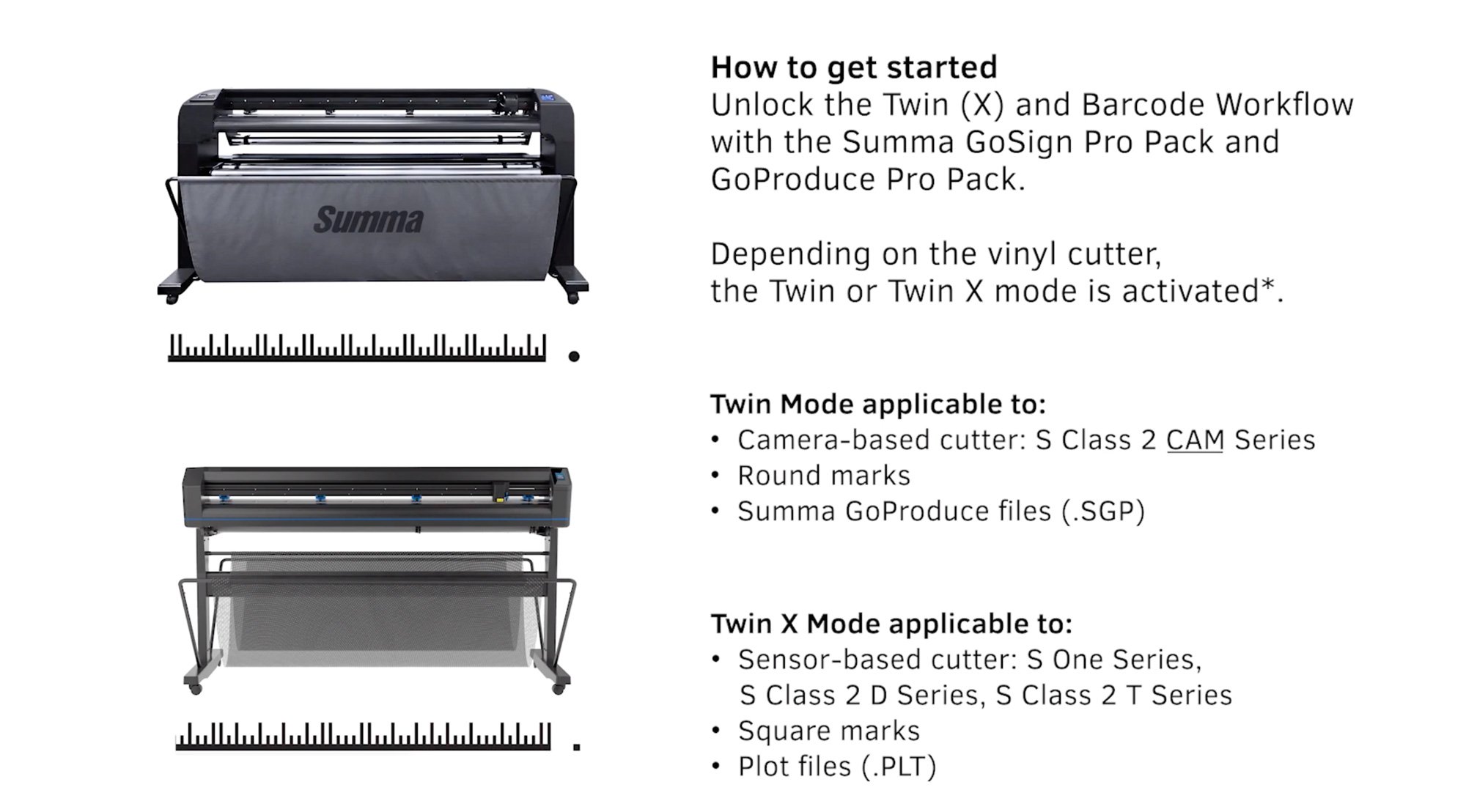

The Pro Packs of GoSign and GoProduce both include the Twin workflow and also the Barcode workflow. The Barcode workflow generates an autonomous workflow where an entire roll of vinyl is cut unattended. Ideal if you are looking for a highly automated workflow with minimal operator intervention. The combination of the Twin and Barcode workflow is, in other words, about the most efficient and productive workflow there is to be found.

Differences between Twin and Twin X mode

Within the Twin Workflow, Summa offers two different modes: the Twin and Twin X mode. Although both modes look similar at a customer level, when you look more closely at a technical level, there are important differences to consider.

The Twin mode is applicable when using a Summa F Series flatbed cutter in combination with a camera-based cutter from the Summa S Class 2 CAM Series. For this workflow, we use the driver of the flatbed cutter to control the OPOS CAM cutter in GoSign and the flatbed cutter in GoProduce. This mode only works with round registration marks and reads Summa GoProduce files (.SGP). You can place as many registration marks as you want here, allowing you to cut the tiniest details very accurately.

The Twin X mode is applicable when using a Summa F Series flatbed cutter in combination with sensor-based (OPOS X) cutters from the Summa S One, S Class 2 D and S Class 2 T Series. For this workflow, we use the driver of the vinyl roll cutter to control both the roll cutter in GoSign and the flatbed cutter in GoProduce. This mode only works with square registration marks and reads all plot files (.PLT). An advantage here is that all RIPs with a cutter driver are automatically ready to use Twin X.

To view this content, you need to accept functional cookies.

Change cookie preferences