Product 29.06.2023

Every person cutting and finishing printed or non-printed media knows how vitally important software is for the usability and productivity of your hardware. The presence of an intuitive interface, easy navigation, and intelligent features help the operator handle jobs more efficiently.

At Summa, we recognize the importance of software explicitly tailored to the hardware. To put words into action, Summa developed its own in-house software platform, GoSuite. GoProduce Flatbed Edition is our F Series software module designed to optimize the F Series users’ workflow.

Our GoProduce software does not only have an intuitive interface and modern look that help you navigate the platform with ease, it also has a lot of interesting features that can help you improve your workflow! Here is just a small selection of the features we offer:

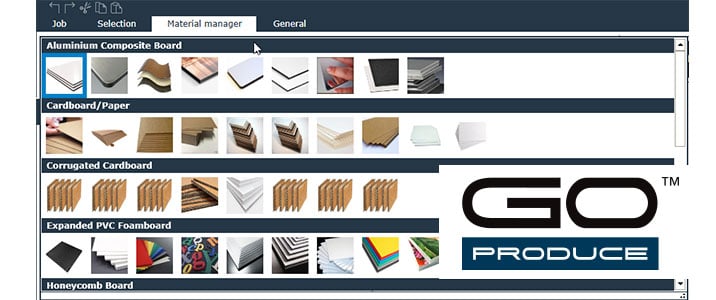

The Material Manager is vital to the user-friendliness of the GoProduce software. It includes an extensive range of material types, which contain the cutting settings and tool data created by Summa. These material settings can be adapted to your specific needs at all times.

The Material Manager ensures smart collaboration between jobs, materials, and available tools. The operator can choose an existing material or create a new one. This includes predefined methods and parameters, meaning that you only need to choose the material you want to process, and the material manager will automatically load the correct settings.

Backside cutting is especially useful if you don’t want to damage your print on the outside of the media, like with cardboard boxes. GoProduce includes a specific camera profile that enables you to perform backside cutting with edge detection.

How exactly does it work? The camera reads the marks on the print first, then the edges of the sheet. After that, you flip the sheet, and the flatbed cutter rereads the edges to determine the position of the print. Lastly, it cuts your media, leaving you with a perfectly finished product.

Flatbed cutters usually need an operator to select the right cutting file, read the printed marks to register the correct position of your design, and compensate for the selected cutting file.

With the barcode functionality, the flatbed reads the printed barcode, identifies the job and automatically opens the corresponding file in the software. Once all the material settings have been applied, it is automatically sent to the cutter, who will then execute the job.

See how it works in the video below:

To view this content, you need to accept functional cookies.

Change cookie preferences

A new version, GoProduce Flatbed Edition V3, is now available, and it has some great new features:

Go ahead and make your cutting workflow (even more) efficient and straightforward with our GoProduce Flatbed Edition software.

Original date: 28/04/2020